Copper products are widely used across HVAC, refrigeration, plumbing, and mechanical systems in the UAE. However, the terms copper coil, copper tube, and copper pipe are often used interchangeably, even though their structure, usage, and measurement standards are different. Understanding these differences helps engineers, contractors, and buyers select the right copper product for performance, durability, and compliance.

This guide explains the practical difference between copper coils, tubes, and pipes, based on application, flexibility, measurement, and strength commonly followed in Dubai and across the UAE.

Copper Coil / Copper Tube

Copper coils are primarily used in air conditioning and refrigeration systems where efficient heat transfer is required. A copper coil is essentially copper tubing supplied in a coiled form, making it easy to transport, bend, and install without excessive fittings. Refrigerant or fluid flows through the coil to absorb or release heat, making copper coils essential for split ACs, VRF systems, chillers, and cold rooms.

Copper tubing is malleable and can be bent or shaped without significant force. This flexibility reduces joint requirements and minimises the risk of leakage, which is critical in HVAC applications operating under pressure. The diameter of a copper tube plays an important role in determining its strength and pressure-handling capacity, especially in structural or mechanical systems.

Copper tubes are manufactured with tighter dimensional tolerances compared to pipes. They can be round, square, rectangular, or oval, depending on the application. In HVAC and instrumentation systems, copper tubes are hollow and designed to perform reliably under pressure. Due to their strength and precision, copper tubes are widely used in mechanical and refrigeration systems throughout the UAE.

Copper Pipe

Copper pipes are rigid, straight copper sections used mainly for fluid transportation. These fluids may include potable water, hot water, gas, or steam. Copper pipes are commonly found in residential villas, commercial buildings, and industrial plumbing systems across Dubai and the wider UAE.

Unlike copper coils or tubes, copper pipes are not easily bendable. Directional changes require fittings such as elbows or couplings. Copper pipes are selected based on their internal capacity, which determines the volume and pressure of fluid that can pass through them. Their circular shape helps maintain consistent pressure during fluid flow, making them suitable for plumbing and heating systems such as boilers and radiators.

Measurement Difference Between Copper Pipe and Copper Tube

Copper tubes and copper pipes follow different measurement standards, which is a key technical distinction.

Copper tubes are measured by their outside diameter (OD) and wall thickness, often referred to as the schedule. These measurements may be specified in millimetres or inches. A thicker tube wall generally provides greater strength and durability, especially in HVAC and refrigeration systems.

Copper pipes, on the other hand, are measured by their nominal inside diameter, known as Nominal Pipe Size (NPS or DN). This sizing system represents the approximate internal diameter of the pipe and is used to calculate fluid flow capacity. NPS standards are commonly applied in plumbing and piping specifications.

Nominal Pipe Size and Schedule Reference

| Nominal Pipe Size | Outside Diameter (OD) | Schedule 5 | Schedule 10 | Schedule 40 | Schedule 80 |

| 1/2″ | 0.840″ | 0.065″ | 0.083″ | 0.109″ | 0.147″ |

| 3/4″ | 1.050″ | 0.065″ | 0.083″ | 0.113″ | 0.154″ |

| 1″ | 1.315″ | 0.065″ | 0.109″ | 0.133″ | 0.179″ |

| 1-1/4″ | 1.660″ | 0.065″ | 0.109″ | 0.140″ | 0.191″ |

| 1-1/2″ | 1.900″ | 0.065″ | 0.109″ | 0.145″ | 0.200″ |

| 2″ | 2.375″ | 0.083″ | 0.120″ | 0.154″ | 0.218″ |

| 3″ | 3.500″ | 0.083″ | 0.120″ | 0.216″ | 0.300″ |

| 4″ | 4.500″ | 0.109″ | 0.134″ | 0.237″ | 0.337″ |

| 6″ | 6.630″ | 0.109″ | 0.134″ | 0.280″ | 0.432″ |

General Characteristics of Copper Tube and Copper Pipe

Size and Form

Copper coils and copper pipes are generally available in round shapes. Copper tubes, however, can be manufactured in round, square, rectangular, or oval forms depending on application requirements. Pipes are usually preferred for larger fluid systems, while tubes are selected for precision and mechanical uses.

Flexibility and Workability

Copper tubes and coils are flexible and can be bent easily due to their ductile nature. This makes installation simpler and reduces the need for additional fittings. Copper pipes are rigid and require tools and fittings to change direction.

Telescoping Ability

Copper tubes can be telescoped, meaning one tube can be inserted into another. This feature is not possible with copper pipes and is often required in mechanical and HVAC applications.

Manufacturing Process

Copper tubes can be produced using both hot-rolled and cold-rolled processes. Copper pipes are typically manufactured using cold rolling only, which limits their formability compared to tubes.

Strength and Pressure Consideration

Copper tubes generally offer higher structural strength due to controlled wall thickness. Copper pipes are selected based on pressure rating, flow capacity, and internal diameter, especially for plumbing and fluid transport systems.

Corrosion Resistance and Heat Conductivity

Both copper tubes and copper pipes provide excellent resistance to corrosion and are suitable for the UAE climate conditions. Copper’s high thermal conductivity makes these products ideal for HVAC, refrigeration, and heat transfer applications.

Conclusion

Although copper coils, tubes, and pipes are sometimes referred to using the same terminology, their functional differences are significant. Copper coils and tubes are preferred for HVAC and refrigeration systems, while copper pipes are mainly used for plumbing and fluid transportation. Selecting the correct copper product based on application and measurement standards ensures system efficiency, safety, and long-term reliability.

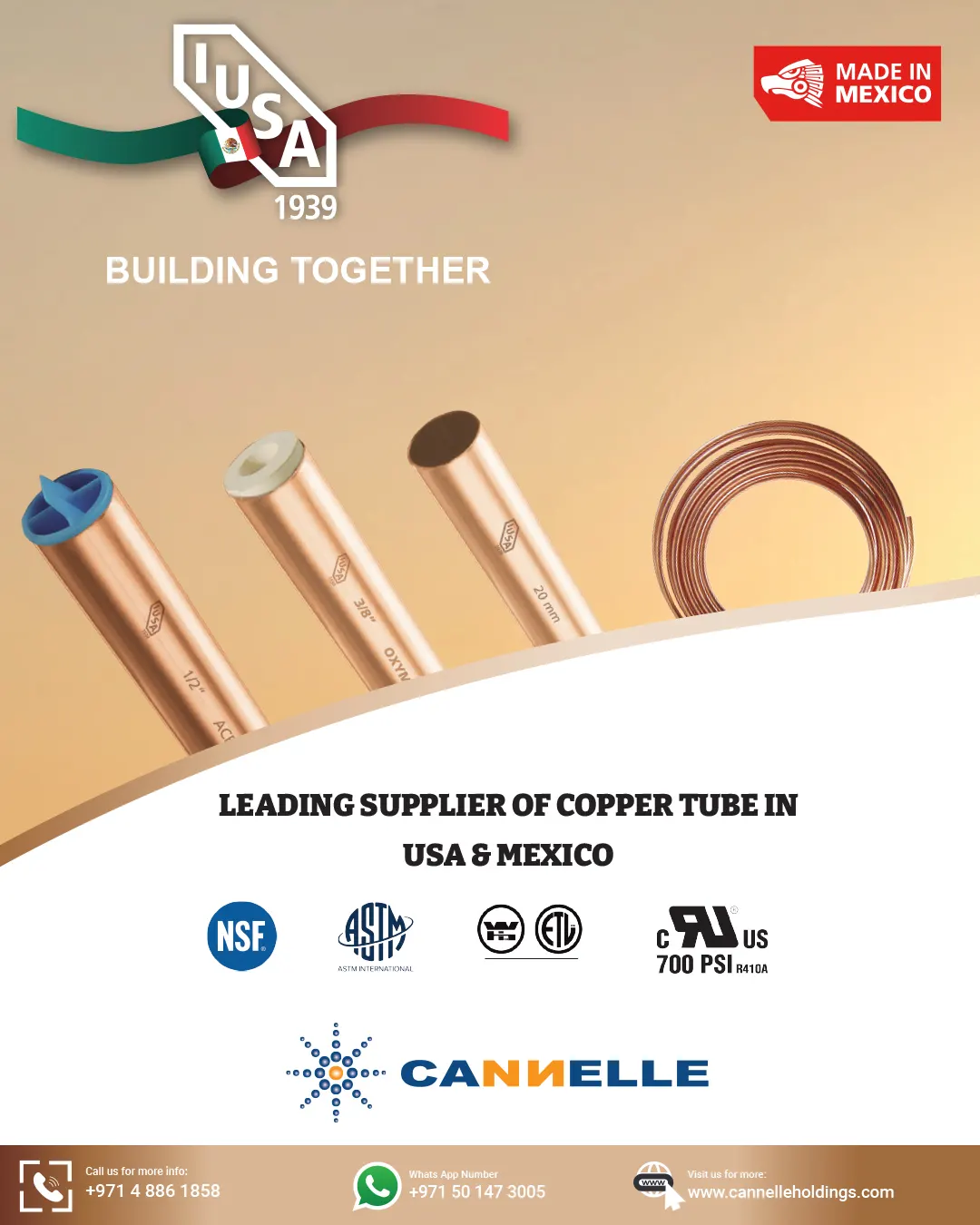

For high-quality copper coils, copper tubes, and copper pipes in Dubai and across the UAE, Cannelle Holdings supplies reliable solutions for HVAC, plumbing, and mechanical applications.